Cycling Clothing Manufacturing Process

Your custom cycling clothing is made from a variety of materials, including polyester, nylon, and spandex. The fabric is first cut into panels according to the design of the garment. The panels are then sewn together using a variety of techniques, including flatlock and overlock stitching. Once the garment is sewn together, it is heat-pressed to set the shape and prevent the fabric from fraying. Finally, the garment is inspected for quality and then packaged for shipping.

Here is a video that shows every aspect of ECYKER’s cycling clothing production in detail.

How We Make Cycling Clothing Step By Step

#1 select raw materials

Our modern cycling jerseys are made from technical synthetic fabrics. They bring together the best properties of elastane, polyester, and nylon, to create great cycling jerseys that wick away sweat, stretch easily without losing shape, improve breathability, and even water resistance or wind-blocking properties.

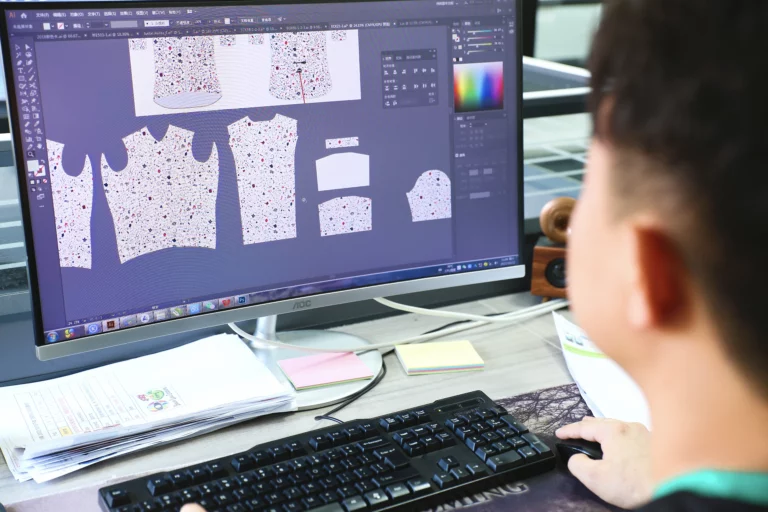

#2 Put Your Design on clothing panels

#3 Digital Printing

#4 Sublimation

We use high-capacity rotary presses to print fabrics for cycling clothing. Sublimation is a process where the colored design of the sublimated paper is transferred to the fabric by heat and pressure. We pay close attention to accuracy to ensure that the designs are properly transferred to the fabric, even for small or intricate details. This allows us to create high-quality cycling clothing with vibrant designs that are sure to turn heads.

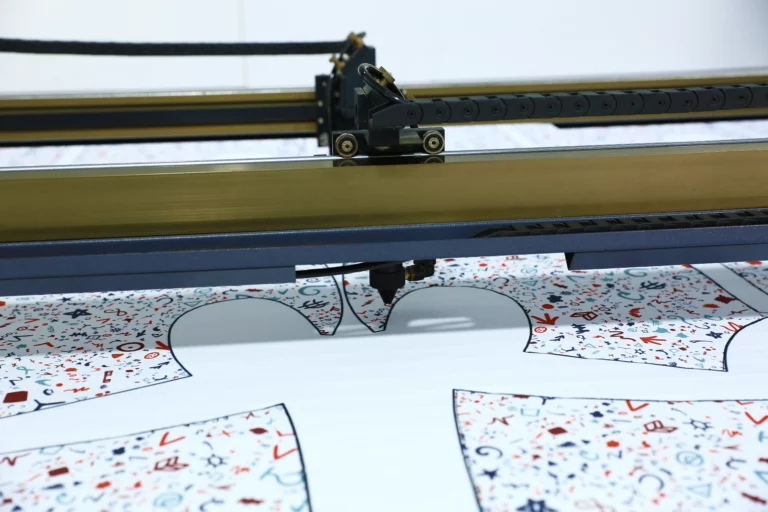

#5 Laser Cutting

As one of the few manufacturers of cycling clothing, we cut fabrics on a modern computer-controlled CNC laser cutter machine which guarantees the high accuracy of all parts of each product. For maximum customer satisfaction, we have already developed over 10 of types of cuts for cycling apparel that are ready for you to use.

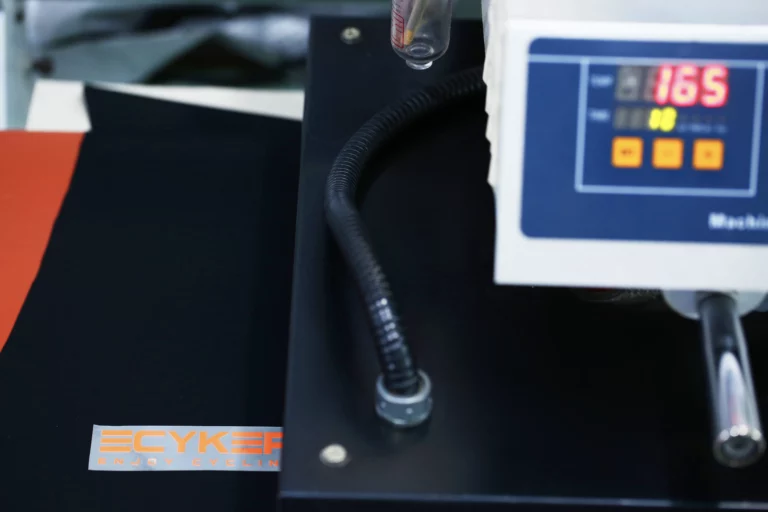

#6 Logo Heat Pressing

Heat transfer label is a perfect choice for customers who want to add a logo to the garment. We have over 40 different label styles for customers to choose from.

#7 sewing

#8 Inspection

#9 Ironing

#10 Packaging

Behind Made In

We are passionate about cycling clothing manufacturing. With 8 years of experience in the industry, we have developed a reputation for producing high-quality products at a competitive price. We use only the finest materials and construction techniques to ensure that our garments are durable and comfortable to wear. We also maintain strict quality control standards to ensure that our customers receive only the best possible products. Our team is dedicated to providing you with the best possible experience, from start to finish.

The Only Way Forward: Eco-Friendly Manufacturing

As the awareness of sustainable manufacturing and development is increasing day by day, ECYKER has been taking a step ahead as the advocator of green cycling clothing production and taking a firm stand when it comes to environment protection.

We cater to the world-wide trend and our clients’ requirements. Our reform is evidenced in each step of manufacturing from raw material selection to processing.

By adopting new tech, we are endeavoring to deliver not only new cycling clothing, but also the new way of apparel production, and your brand’s attitude towards our planet.

-

BSCI, OKOTEX-100 Certificated Fabric

We are proud to use BSCI and OKO-TEX 100 certified fabrics in our products

-

Recyclable Material and Processing

We always follow the concept of environmental protection, so most of our materials can be recycled. -

Energy Saving Equipment and Facility

All our machines are powered by electricity and are environmentally friendly with no polluting emissions. -

Less Waste in Production

We carefully lay out each design for production to reduce the waste caused by fabric cutting.